Επαγγελματικές λύσεις

Οικιακές λύσεις

Η Εταιρεία

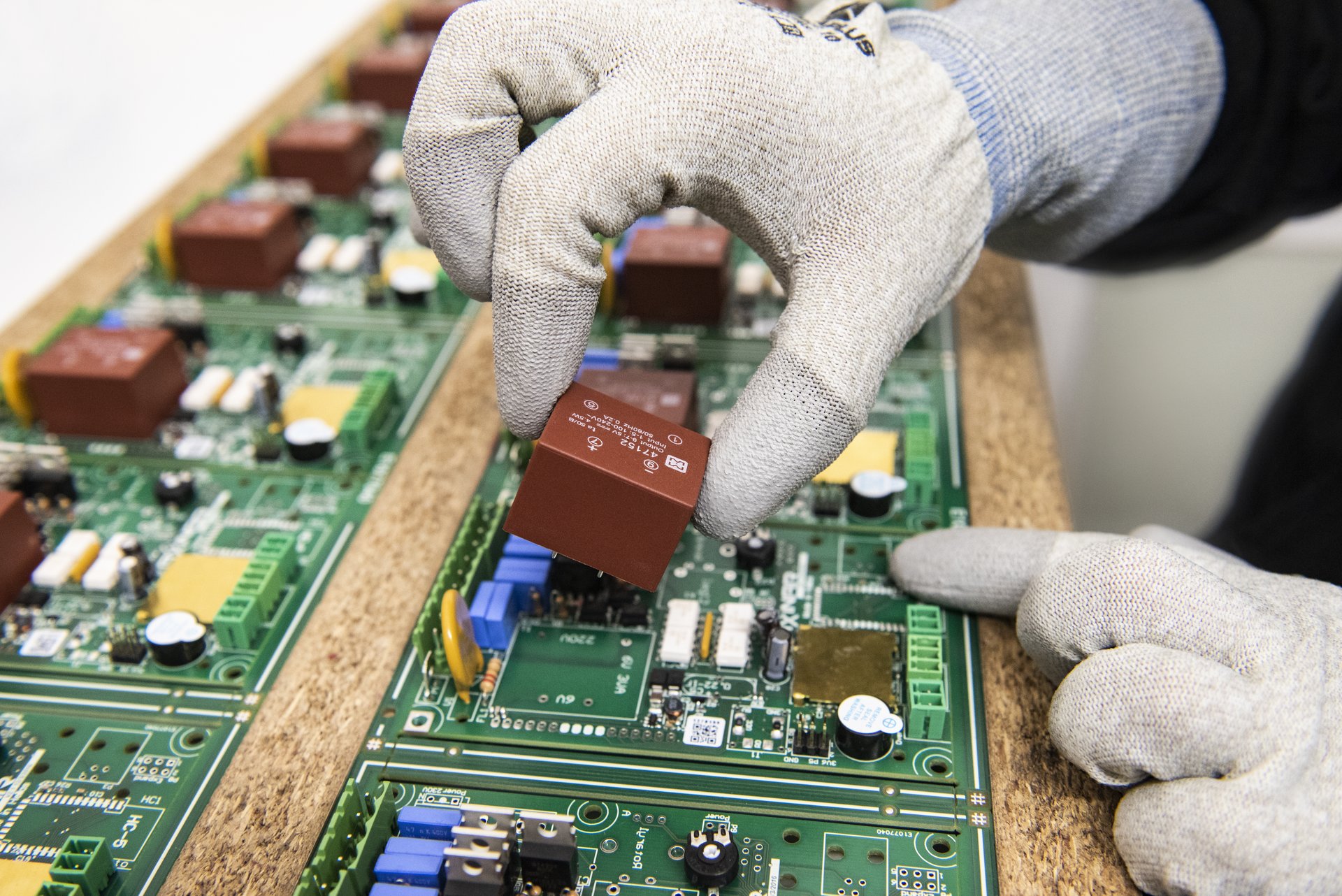

Στην Axinar διακρινόμαστε για τη συνέπεια λόγου και πράξης. Ο εκτενής αριθμός ικανοποιημένων πελατών μας και η ραγδαία ανάπτυξη της εταιρείας μας αποτελούν ισχυρή απόδειξη του υψηλού επιπέδου εξυπηρέτησης, της κορυφαίας τεχνογνωσίας και της συνέπειας στις αρχές και αξίες της εταιρείας μας.

Η πελατοκεντρική μας φιλοσοφία αποτελεί σημείο αναφοράς για τις συνεχείς επενδύσεις σε νέες τεχνολογίες και μηχανολογικό εξοπλισμό, προκειμένου να ανταποκρινόμαστε επιτυχημένα στις απαιτήσεις των πελατών μας.

Η ομάδα μας

H πολυτάλαντη ομάδα μας σχεδιάζει προϊόντα που ανταποκρίνονται αποτελεσματικά σε οποιοδήποτε ανάγκη σας με ακεραιότητα και αίσθημα ευθύνης.

John Harris

CEO & Founder

Patrick Conno

Mechanical engineer

Natalie Williams

Project manager

Mark Thornton

Electrical engineer

Jennifer Healy

Automation engineer

Marie Collins

Industrial designer

Δεν ακολουθούμε τις εξελίξεις, τις δρομολογούμε.

Απολαύστε τα οφέλη της καινοτομίας που σας παρέχει η Axinar.

Tα νέα μας

Η αδιάκοπη υιοθέτηση της καινοτομίας αποτελεί πυλώνα της ανάπτυξής της εταιρείας μας, πάντα με σεβασμό απέναντι την τοπική κοινωνία και το περιβάλλον.

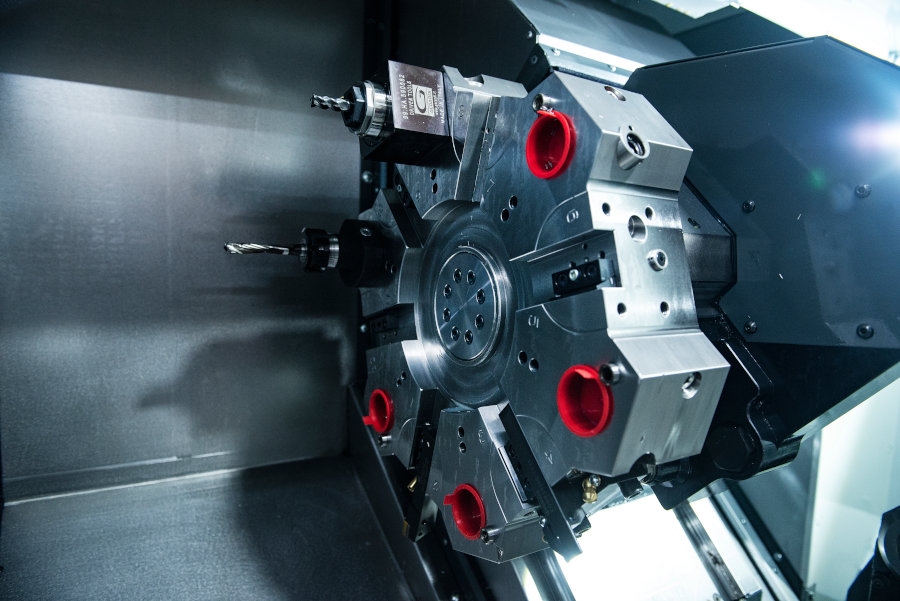

Νew Acquisition – CNC Lathe

At Axinar we look ahead to the future and invest in the total modernization of our production line…

Powerful presence in ISH Frankfurt

Axinar´s participation in ISH Frankfurt, the world's leading international exhibition for sustainable heating technologies, was successfully completed with…

Νέο απόκτημα - CNC τόρνος

Στην Axinar ατενίζουμε το μέλλον με αισιοδοξία και επενδύουμε στον απόλυτο εκσυγχρονισμό της παραγωγής μας με την αναβάθμιση…

Φόρμα Επικοινωνίας

Για οποιοδήποτε αίτημα, παρακαλώ συμπληρώστε την παρακάτω φόρμα και αποστείλετέ την στο αρμόδιο τμήμα.

Σημείωση: Τα στοιχεία σας παραμένουν αυστηρώς εμπιστευτικά, σύμφωνα με τις διατάξεις της Πολιτικής Προστασίας Προσωπικών Δεδομένων της εταιρείας μας.